.jpg)

In this three-part series, we’ve examined ABTech’s role in assembling the optical module for a NASA space telescope; part 3 concludes the journey with validation testing, the launch of NuSTAR, and some resourceful repurposing by ABTech.

ABTech was committed to verifying that the precision motion machines they built were ready to work flawlessly, which is exactly how NASA was counting on them to perform.

In part one, the teams set their acceptance criteria for ABTech’s portion of the lens assembly module. In part two, the scope grew, with ABTech taking on the simultaneous fabrication of identical units to meet NuSTAR’s tight launch schedule.

With double the scope, would ABTech still pass the tests?

“It’s the way it works. If we’re putting something together and it’s not quite right, we’re going to take it apart and make it a better product, regardless of what it does to our cost; customer satisfaction is so important to us.” ~Ken Abbott, CEO ABTech

Reaching the Finish Line

Everybody on the team was serious about proving the machines’ functionality. Consulting engineers were at ABTech for an entire week, reviewing the testing and reproducing the results. Then, after the handover, the machines underwent additional offsite testing.

Both machines passed every test and were approved to build NuSTAR’s optics module. ABTech sent them to the Nevis Astrophysics Lab at Columbia University to start production.

Columbia’s team had experience with a similar prototype, but the new units were bigger and more versatile. ABTech provided on-site installation, setup, and a three-day training session to get them up to speed. After the training, scientists at Columbia immediately began production on the lens assembly. Both machines performed as expected right from day one.

All 4,680 specialty lenses were assembled onto NuSTAR in less than six months.

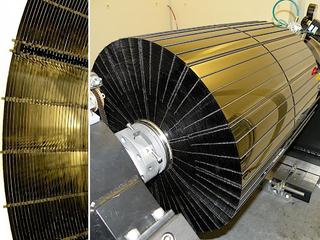

NASA's NuSTAR satellite complex set of optics. Image credit: NASA/JPL-Caltech

NuSTAR Launches

The NuSTAR telescope shot over the Pacific Ocean affixed to a Pegasus rocket that took it into orbit on June 13th, 2012. It completed its two-year primary mission, and the telescope continues operation to this day, helping us understand black holes, supernova remnants, and collapsed stars.

“We’re extremely proud of the part that ABTech played in this exciting project. Our custom solutions process paired with our technical expertise allowed us to deliver a machine that performed beyond expectations.” ~Ken Abbott, CEO ABTech

The fairing is installed on the NuSTAR satellite to protect it as it travels through the atmosphere and into space. Image credit: U.S. Air Force/Doug Gruben

The story of ABTech’s NuSTAR machine continues…

ABTech’s custom engineering approach played an important role in the success of the NuSTAR build. With a goal of collaboration and innovation, ABTech supported this exciting mission by making a machine that’s out of the ordinary.

Air-bearing devices retain an intrinsic value even after a project is complete. One of the NuSTAR machines is now back in-house where it’s being repurposed for another application.

Far from obsolete, the NuSTAR machine will continue to make precision parts, capturing its existing asset value and proving ABTech’s legacy of quality.

ABTech solves custom challenges – contact us!

Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.