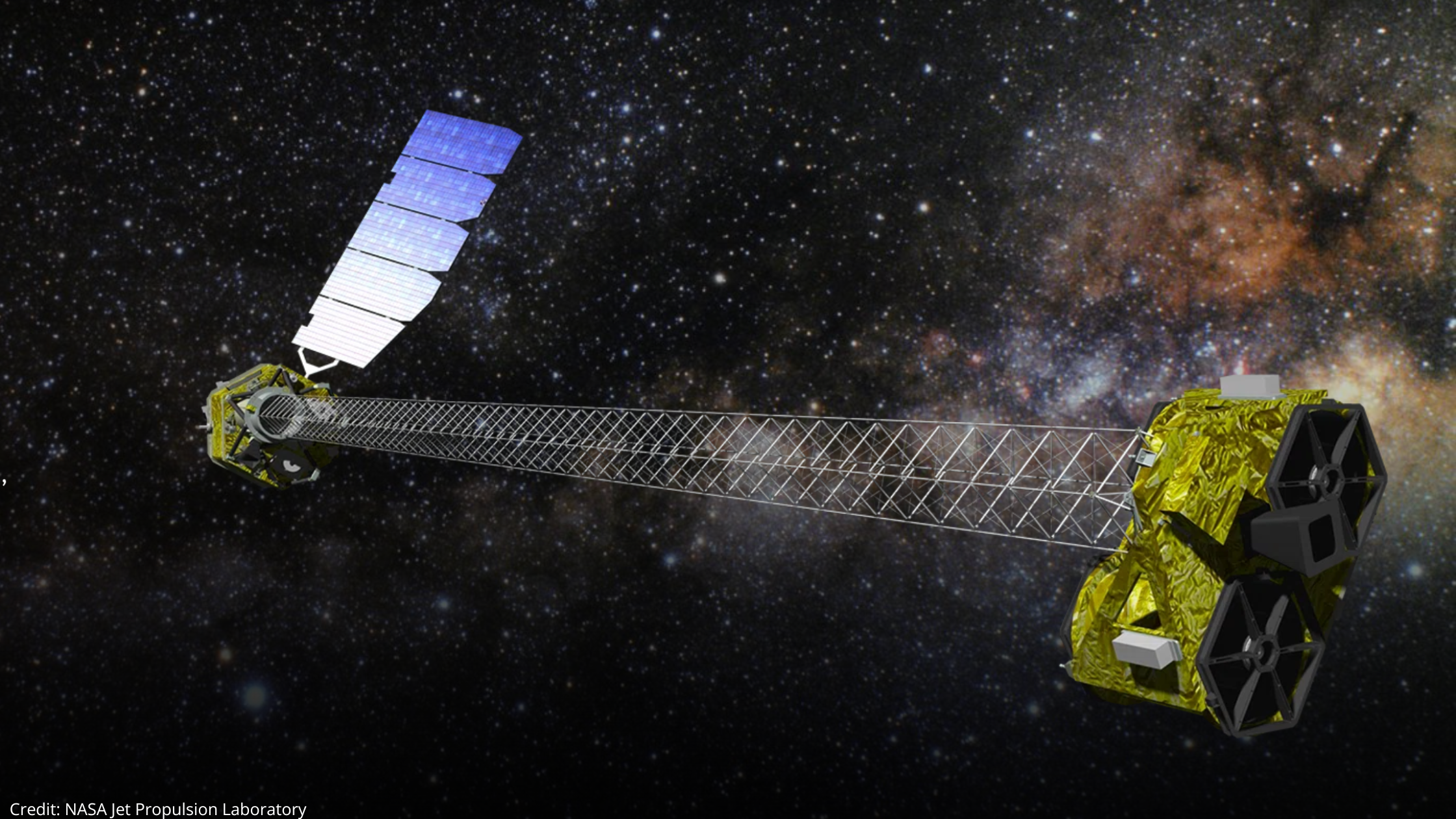

Image credit: NASA Jet Propulsion Laboratory

In this series, we’ll recount how ABTech’s expertise shaped the lenses of NASA’s NuSTAR space telescope; part 1 looks at the project approach, engineering design, and plans for validation.

As the NuSTAR telescope observes another year in space, the entire ABTech team celebrates this great accomplishment alongside our customers, partners, and vendors.

In 2008, ABTech was the successful bidder for an ambitious project—they were to pioneer a precision motion machine to manufacture the lens module of a new space-based telescope for NASA.

The Nuclear Spectroscopic Telescope Array, or “NuSTAR” for short, was developed by NASA. The telescope would focus high-energy X-rays so scientists could expand their view of deep space. “NuSTAR will open up a whole new window into the universe,” said Charles Hailey, Professor of Physics and co-director of Columbia University’s astrophysics lab.

Opting for a Partnership Approach

ABTech’s team centered their bid on a custom solution for NASA. Customization was essential for building a precision motion machine to assemble NuSTAR’s 4,680 specialty lenses.

It was the highest-profile project ABTech had taken on to date, and CEO Ken Abbot knew it’d push their technical capabilities, but he had confidence they could deliver.

“This project was a perfect example of how ABTech has been able to look at a customer’s requirement (in this case, to build an optics module for outer space) and design and build a precision machine capable of meeting their needs,” – Ken Abbott, CEO ABTech Manufacturing

To develop an exceptional design for the NuSTAR machine, ABTech trusted their engineering solutions process.

Step 1: Beginning with the End

ABTech’s proven process starts by meticulously identifying what a customer wants to achieve once the project is complete. The NuSTAR project was complex right from the start because of the technical requirements and the number of organizations involved in building the advanced telescope, including:

- Columbia University’s Nevis Astrophysics Lab

- The California Institute of Technology

- NASA’s Jet Propulsion Laboratory

- Los Alamos National Laboratory

- Goddard Space Flight Center

During the project, Columbia University (responsible for assembling the telescope’s lens module) and the team from ABTech worked closely together.

Step 2: Putting Expertise to Work

NASA supplied the exact specifications for NuSTAR’s optical components, and to create the optics assembly, ABTech’s machine would have to perform diamond turning, grinding, assembling, epoxying, and measuring.

The final design was a turnkey, CNC, air-bearing-based precision motion device that combined air-bearing linear slides and high-speed spindles.

The performance specifications were ambitious (as expected of a NASA project). The linear slide accuracy was to be 1µ or better (40 millionths of an inch over 24 inches), and the spindle had to reach 10,000 revolutions per minute. Delivering results like these would be a challenge.

Step 3: Planning for Validation

A critical part of the NuSTAR project was determining what success would look like. ABTech worked with Columbia University to develop a conceptual design for the machine. At the same time, they laid out the acceptance criteria for final testing and approval.

Up Next in Part 2…

With NuSTAR’s launch date less than a year away, there weren’t enough days to fabricate all 4,680 lenses. NASA wanted the manufacturing time cut in half!

In Part 2 of this series, we’ll see how the time crunch got eclipsed.

Discover more about ABTech’s Custom Engineering Solutions.

Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.