In this three-part series, we look over ABTech’s contribution to the lenses of NASA’s NuSTAR Telescope; part 2 covers the project’s daring timeline and high standards of workmanship.

ABTech was working closely with Columbia University’s Nevis Astrophysics Lab to manufacture an optics module that would assemble NuSTAR’s 4,680 specialty lenses.

In Part One, the teams finalized a design and acceptance criteria—but there was an issue. A single optics module wouldn’t finish the task before NASA’s launch date.

“They had a hard launch date. And if it was missed, the project went back into rotation for a year later. There’s no way they were going to miss it.” ~Ken Abbott, CEO ABTech

With dozens of stakeholders waiting for the completion of NuSTAR’s lenses, ABTech boldly agreed to keep the project on track by fabricating two identical machines simultaneously.

The ambitious schedule left no time for prototypes and no room for error or rework.

Ensuring Precision & Accuracy Throughout the Build

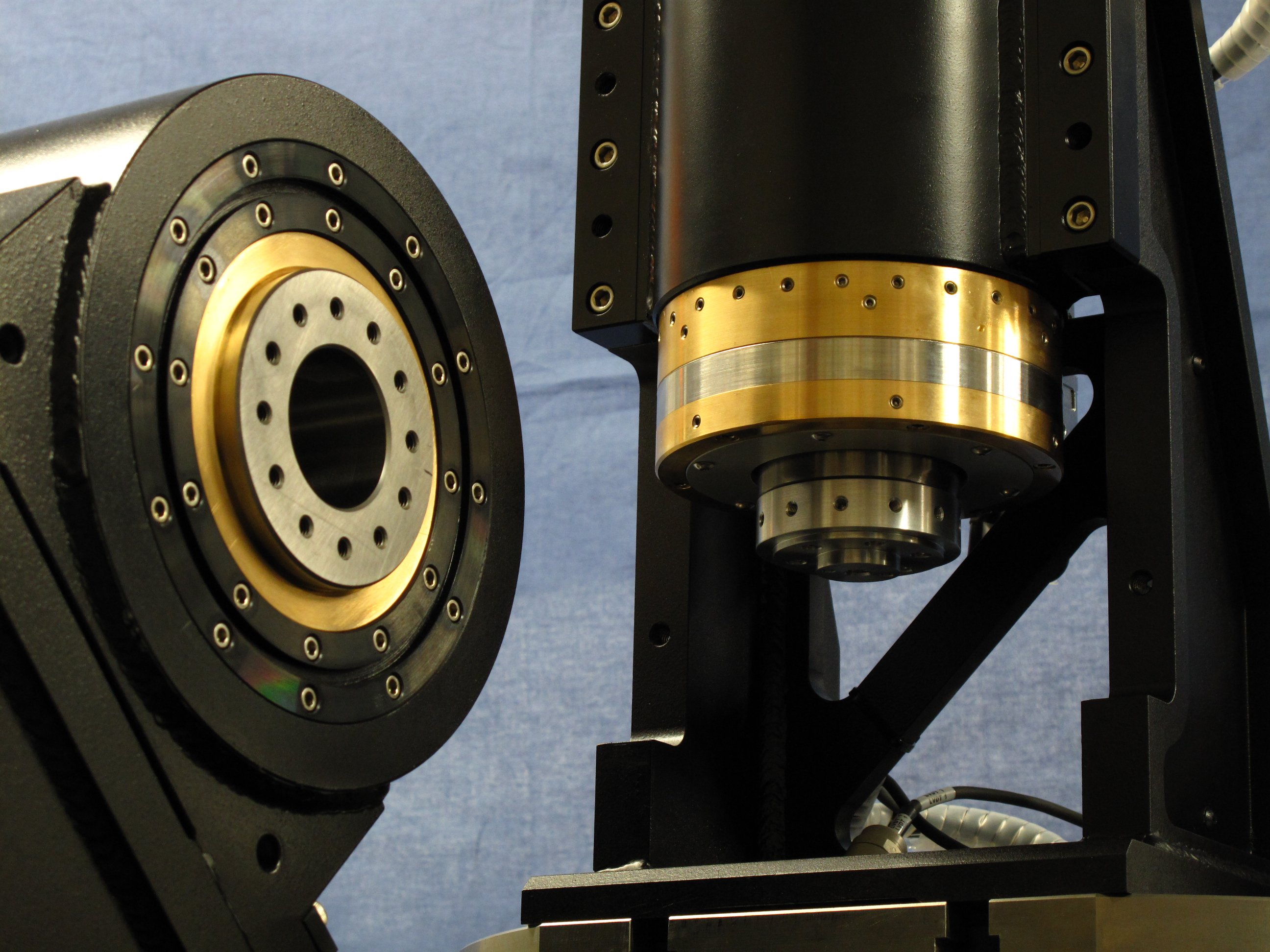

Air bearings were the only technology that would perform successfully in assembling the NuSTAR telescope’s lenses—with no friction between the moving surfaces, the linear stages and spindles could reach sub-micron accuracy with absolute repeatability.

Achieving the performance requirements was tricky, even for an expert precision-motion supplier like ABTech. The spec for the optics module was uncompromising. It stipulated a positional accuracy within 1µm, straightness of 1µm over 600mm of travel, and near-perfect perpendicularity between the X and Z axis.

An Ambitious Build that was Shooting for the Stars

The NuSTAR optics assembly module was to be a turnkey device; each machine featured:

- Linear stacked air-bearing stages

- Air-bearing work-holding and tailstock spindles

- Lathe operation or holding during assembly and grinding

- High-speed air bearing spindle (10,000 rpm)

- Vertically mounted for grinding graphite optic mounting surfaces

- Indexing turret assembly

- For a smooth transition between diamond turning, grinding, and measurement functions

- Granite surface plate and base frame

- CNC lathe controller and electrical control cabinet

A commitment to continuous improvement underlies every ABTech project. And, while the looming deadline was imperative, the teams did manage to incorporate some performance and functionality adjustments. A solutions approach brought these valuable changes into the build without impacting the final delivery.

Building NuSTAR with Pride in Precision

This satellite-based telescope project included ABTech’s most accurate work to date, and the team was over the moon, but it wasn’t yet time to breathe a sigh of relief. The machines had to be tested against the strict acceptance criteria established in the design phase.

It was the moment of truth.

Up Next in Part 3…

NASA planned to launch NuSTAR via Pegasus rocket into low Earth orbit. But before that, after nearly six weeks of tuning, tweaking, and adjusting, it was time to prove that ABTech’s air-bearing devices met specifications.

In Part 3, the exciting conclusion, we’ll see if the test results were out of this world.

Discover more about ABTech’s Custom Engineering Solutions.

Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.