Trust is integral to nearly every business relationship. It’s the basis of contracts, commercial transactions, and more. Similarly, trust is a foundation for innovation, allowing specialty manufacturers like ABTech the freedom to enact a customer’s vision.

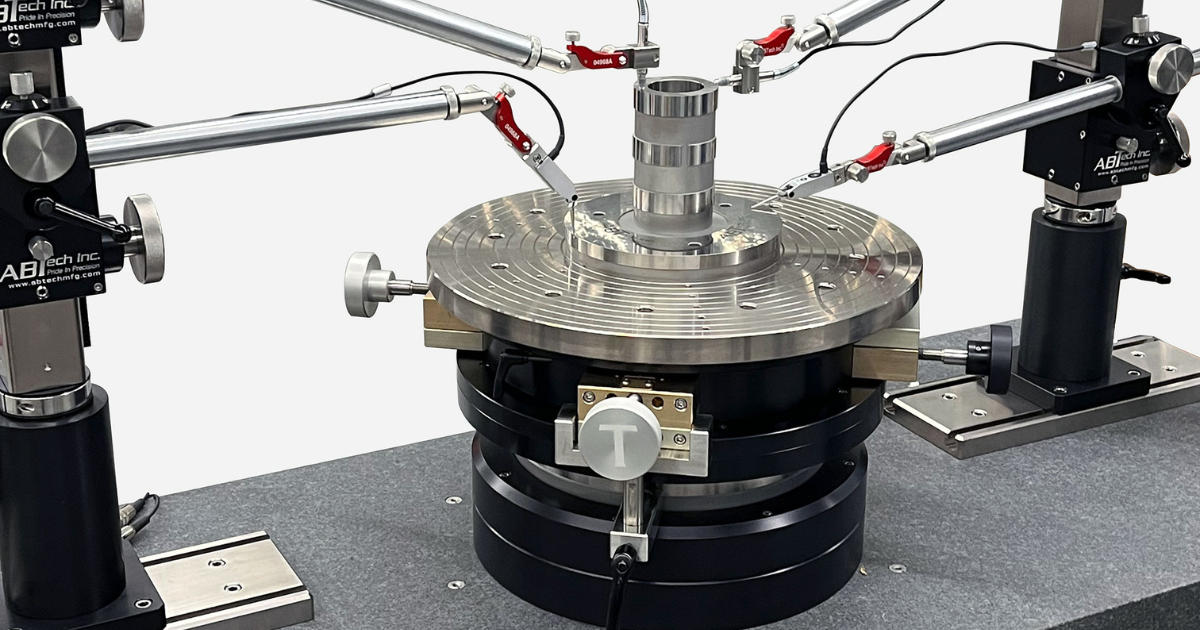

As an example, consider ABTech’s custom work on building jet engine rotary tables for GE Vernova. The table was for rotor repair and assembly; it required ultra-precision (0.24 microns) and high load capacity (35,000 pounds). For more details, read that case study here.

What is it about ABTech that inspires confidence in major corporations? Here are seven reasons drawn from customer feedback.

Reason #1: Competitive Pricing

Despite offering one-of-a-kind builds that push the limits of achievable accuracy, ABTech maintains competitive pricing. In fact, a key consideration of GE Vernova’s selection was affordability without sacrificing quality.

Manufacturing a tailor-made device like a spindle, linear slide, or rotary table may sound expensive, but it doesn’t have to be. ABTech embraces the concept that “custom” doesn’t mean reinventing the wheel every time.

To learn about how we control custom machinery pricing, read The Art of Controlling Costs in Custom Machine Design

Reason #2: Precision Motion Expertise

As leaders in the precision motion world, ABTech’s skills are second to none. GE Vernova knew that very few companies had the deep knowledge and years of experience needed for its project.

As Brandon Malone of GE Vernova reflects, “There’s only a handful of companies in the world that can make these types of tables. They’re precision tables. They’re holding tolerances in the millionths of an inch.” A commitment to innovation makes ABTech a preferred partner for corporations that value staying at the forefront of technology.

In addition to the projects with GE Vernova, ABTech is also the sole licensed supplier of GE Aerospace Genspect systems.

Learn more about our Engine Assembly Systems

Reason #3: Agile Project Management

Agile projects retain the flexibility to adapt to customer feedback and unplanned changes. Getting creative and finding solutions when obstacles arise is a valuable asset for a precision motion vendor creating custom equipment.

With a passionate team of technicians and engineers, ABTech brings projects from point A to point B without losing focus on the customer’s deadline or final performance requirements.

Reason #4: Qualifications, Certifications, and Paperwork

Beyond manufacturing expertise, successfully qualifying to work with a global enterprise is an achievement in itself.

In large corporations, there’s always plenty of administration to conquer to become an approved supplier. ABTech is comfortable working hand-in-hand with companies of all sizes and can supply the qualifying paperwork for most procurement, contractual, or safety requirements. Many respected names have trusted ABTech and have not been disappointed.

Read about some of ABTech’s interesting custom projects.

Reason #5: Exceptional Collaboration

Large companies with complex engineering needs (like those that build jet engines) prefer to partner with ABTech because of its team-wide dedication to collaboration. Basically, ABTech is easy to work with, going above and beyond to ensure that customers are satisfied.

A solutions approach emphasizes customer collaboration throughout a project; it’s critical to success. ABTech’s approach is built on a Proven Process, consisting of:

- Discovery

- Collaboration

- Quotation

- Execution

- Implementation

- Follow Up

For example, ABTech's collaboration with multiple stakeholders was key to a project that helped shape the lenses of NASA’s NuSTAR space telescope.

Read about the project: NASA Engages ABTech in Building the NuSTAR Telescope

Reason #6: Supply Chain Security

The global COVID-19 pandemic revealed the risks to supply chains with limited suppliers. Many organizations were unable to source essential parts and equipment when they became scarce. Manufacturers with a broad network of qualified vendors were better able to keep business going.

Vetting and approving multiple vendors increases supply chain resiliency. ABTech (with a robust supply chain of its own) is a trustworthy U.S.-based supplier of precision motion equipment and a valuable addition to strengthening a supply chain.

Reason #7: A Focus on Partnerships

At ABTech, whether we are optimizing jet engine builds or designing another custom solution, we take pride in precision and know that our solutions will deliver value for years, even decades. Sustained customer success is important to us, which is why we design for the long haul, aiming to build potential new business requirements into our products.

ABTech is not just an air-bearing supplier; we are a partner.

If you’re looking for a reliable manufacturer of precision motion technology, why not consider ABTech for your next project? We’ve been in business since 1998, repeatedly proving our capabilities to meet and exceed customer expectations.

ABTech looks forward to supporting your next project.