Precision engineering is a critical part of many advanced industries. Looking at aerospace and semiconductor manufacturing, for instance, it’s clear that stringent standards and sub-micron accuracy demands are the norm.

As industry technologies advance, toolbuilders have to tighten their motion control; many reach out to ABTech to inquire about custom machine design.

An air-bearing device (like a spindle, slide, or lathe) facilitates impressive sub-micron accuracies. However, getting a customized machine can be intimidating, as many assume it comes with a hefty price tag. But that’s not the full truth.

Custom doesn’t necessarily mean expensive—it means making smart decisions to meet both a client’s performance needs and budget.

In this post, we’ll explore the idea of “Cutting Costs, Not Corners,” and you’ll learn about the strategies we at ABTech use to deliver cost-effective, purpose-built precision motion machines.

Sticking to a Proven Process

In over 25 years of manufacturing, we’ve seen what it takes to successfully design a custom precision motion machine for our clients. We’ve turned our learning into a reliable process that works again and again. It’s a framework to guide projects, from managing quotes to collaborating on design, right through to production.

Download the rest of the guide: Customizing High-Speed Spindles

Read more in A Custom Approach to Air Bearing Design

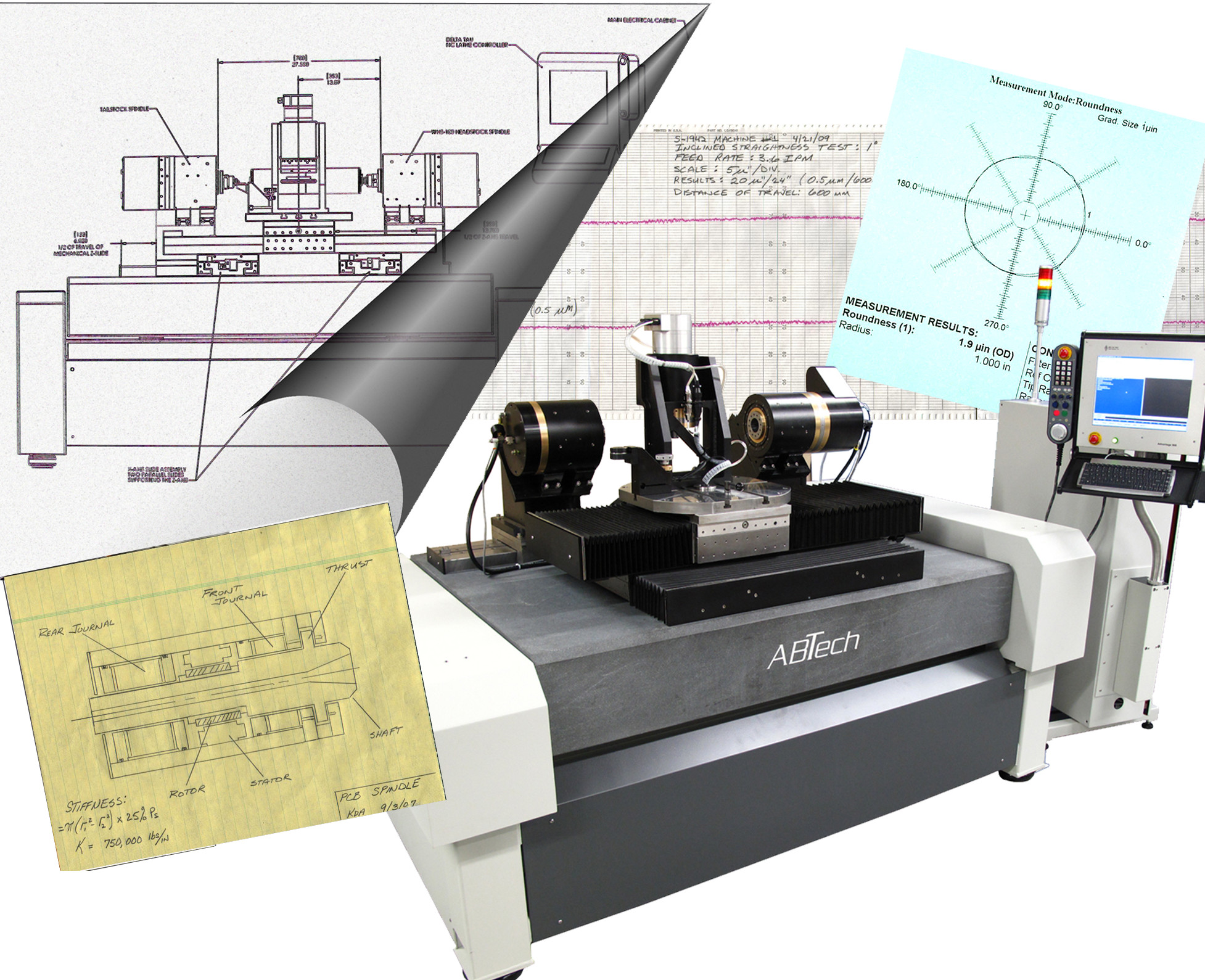

Taking Knowledge from Past Projects

While every custom machine design is unique, the truth is that starting from scratch is rare. ABTech has led so many projects it’s possible to avoid forming an entirely new design. It’s not unusual for much of a custom project to be based on previous solutions, a saving that keeps costs competitive and streamlines the design process.

“We have a whole library of solutions, a huge range of different products and designs we’ve put together, so custom doesn’t mean we’re reinventing the wheel every time.”

~Chris Abbot, ABTech COO

Designing for Specific Priorities

Part of developing (and then controlling) the scope of a custom-designed precision motion device is recognizing the customer’s top priorities. These drivers often include:

- Cost

- Schedule

- Performance

Delivering the right balance between these three keeps customers happy. An up-front understanding of what’s most important to the client confirms the best materials, design, and approach for each project.

“There's a wide range of options that we pick and choose and collaborate with the customer on, depending on what their top priorities are,” explains Abbott. “Whether it's material selection or even the types of motion components we use, such as motors and encoders”

Options start at basic aluminum construction and looser-spec components, up to stainless steel construction with top-of-the-line motion components. Some OEMs order a range of devices from ABTech, giving them the ability to offer their customers a choice of machines with different performances and price tiers.

Including Standard Parts Where Possible

It might seem counterintuitive, but standard offerings are a good starting point for customization as it keeps solutions economical. ABTech uses a group of trusted suppliers and a library of proven designs to streamline builds, saving customers time and money.

Getting the Right Information Up Front

Whether you’re modifying an existing machine tool or creating a prototype project, preparing your documentation will speed up design and delivery. This includes a concise explanation of what you’re trying to solve and the specifics of the environment the machine is going into. Things like:

- The critical specifications for your machine

- If you had a previous solution, where it fell short

- What you're trying to add on (if anything)

- What don't you have today that you're looking to gain

It's rare for a customer to have all of that figured out before a project begins, which is why ABTech’s process includes working together to gather the necessary information.

Taking Time to Get Clear on the Final Design

One of the more important things a customer can do to keep costs from escalating is to be patient and move slowly—deliberately—through the design phase. Take the time up front to be sure of the final design. Last-minute input can lead to a costly cascade of rework.

“It’s when you really focus on design, that in the end a project is much more cost effective.”

Working with ABTech for Custom Machine Design

At ABTech we supply precision motion devices for the most demanding, most advanced industries. We welcome the challenges that others can’t or won’t take on. Talk to us about creating a custom machine that fits your specifications and budget.

Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.