Commissioning a precision motion device involves more diligence than ordering an off-the-shelf unit; it’s about embarking on a journey with a custom machine builder, collaborating throughout the project’s entirety. Understandably, it pays to find a supplier with the necessary skills and experience before committing.

But how do you know when you’ve found the right custom machine builder?

Chris Abbott, COO of ABTech, has been building custom air-bearing devices for more than a decade. He knows the challenges of customization and the rewards of pushing the limits of what’s currently possible in motion accuracy.

In this post, Chris reviews the questions he’d ask to vet a custom machine builder.

Are they truly devoted to custom craftsmanship?

Just because a website mentions customization doesn’t mean it’s a core offering—the supplier might not have the time to handle the workload of a bespoke project. On the other hand, an air-bearing supplier specializing in customized design knows what it’s like to create a one-of-a-kind machine.

“The reason ABTech is so focused on custom machines is the idea that there’s not something out on the market today that fixes a problem for a customer. We might not know how to do it yet, but we’re going to figure it out; that’s what motivates us and inspires the group each time a new order comes in.”

Look for excellence in their past projects

Past performance does not guarantee future success, but experience does reveal technical skills, strengths, and passions. Ask suppliers for case studies, references to contact, or details about similar projects they’ve completed in the past.

“As far as selecting someone, a website can have specifications or statements, but I like to see experience actually proven—you know, real. Not that I’m going to necessarily find an exact solution for what I need, but I can see how they’ve solved similar problems or challenges.”

Can they promise a partnership rooted in understanding?

There’s a lot of involvement from both the customer and manufacturer to successfully build a custom air-bearing machine. If communication breaks down, so do the chances of achieving the best solution. In short, finding a company that values you and your project is important.

“I think what I’d be looking for in a custom supplier, from a communicative level or relationship level, is someone who can talk through the challenge that I’m having now and be able to communicate the problem back clearly without forcing an immediate solution or jumping right to trying to sell me something. Someone who listens.”

Are they responsive to your vision?

Right from the first interaction, judge what it will be like to work with a supplier by noting how long they take to respond to your inquiries for information or a quote.

Do they really want your business if it’s been two weeks and you still haven’t heard back? And if they do eventually respond, do you really want to work with them?

“You can’t just let someone sit there wondering if you’re ever going to get back to them. So, you could respond to them right away, not necessarily with an answer, but saying something like, I don’t have an answer for you right now, but we’re working on it, and you’ll get an answer next week.”

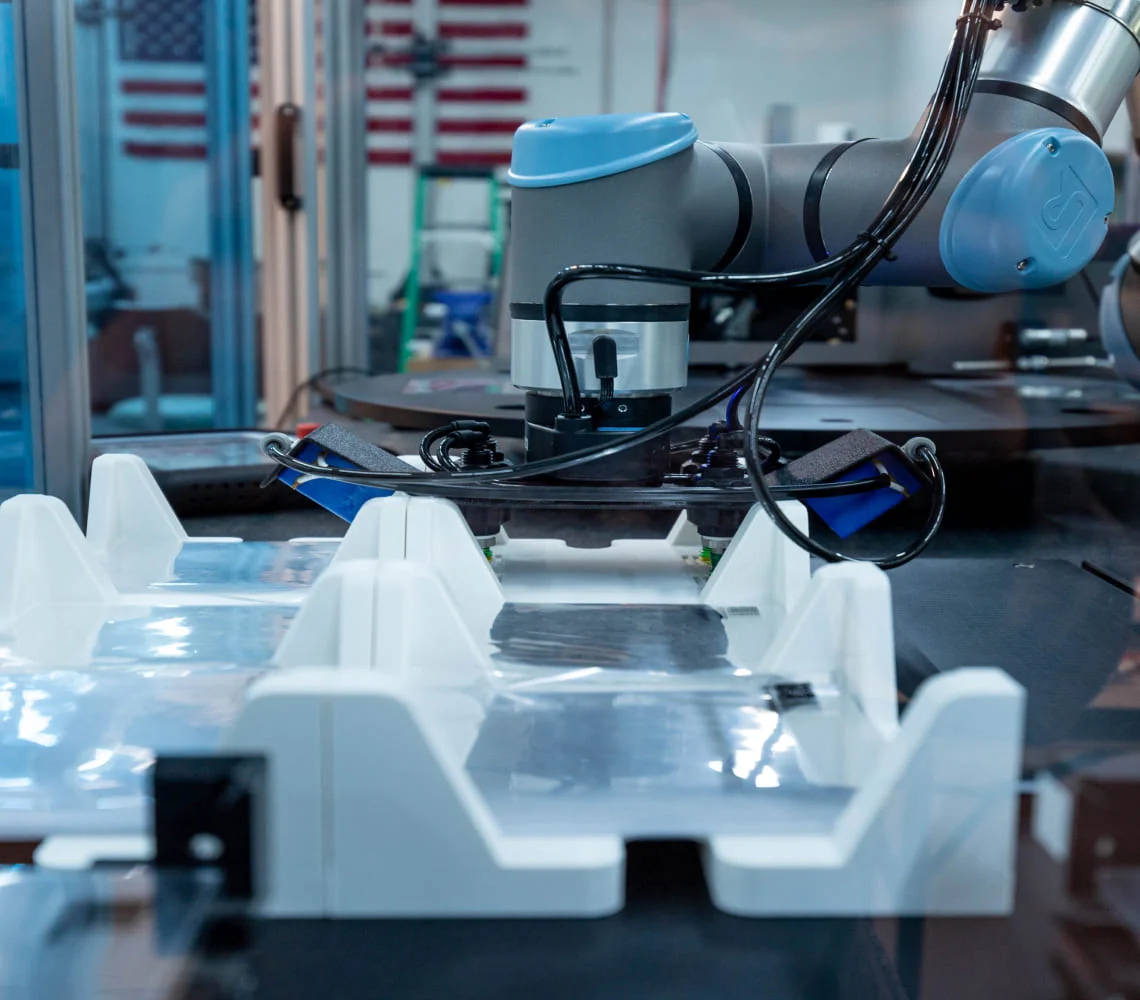

Experience their workshop firsthand!

You learn about a machine builder by visiting their shop. If you’re offered a tour of their facility, that in itself tells you something good about their priorities. And while you’re there, keep an eye out for signs that the company cares.

“When you’re going through, look at the machines and the facility itself, but also consider the overall atmosphere. You can tell when you’re in a machine shop that’s run well, where people have passion in their work. It’s a huge source of pride for ABTech to have the facility we have and take care of it the way we do.”

ABTech Creates Custom Air Bearing Precision Motion Devices

Based out of Fitzwilliam, New Hampshire, ABTech has been in the precision motion business for over a quarter of a century. We specialize in custom air bearing spindles, linear slides, rotary tables, and multi-axis systems—designs others can’t or won’t take on.

We look forward to hearing about what’s challenging your business and how we can work together to create a custom machine that fits your needs and budget.

Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.