In the world of high-accuracy applications, even the smallest movement matters. That's where precision motion components come into play. These specialized parts are engineered to deliver exceptional control, stability, and repeatability — and are the foundation of successful precision motion systems across industries.

Below, we break down everything you need to know about precision motion components in a clear, FAQ-style guide.

What Are Precision Motion Components?

Precision motion components are specialized mechanical elements designed to control and guide movement with extreme accuracy. These components are essential for systems that demand micron- or nanometer-level positioning.

Key types of precision motion components include:

- Rotary Tables: Enable smooth, controlled rotational movement.

- Spindles: Deliver precise rotational motion for machining and inspection.

- Linear Stages: Allow controlled, high-accuracy linear movement.

- Accessories: Support enhanced system performance, such as motion controllers, base structures and vibration dampening equipment.

Why Are Precision Motion Components So Critical?

High-accuracy environments — like semiconductor manufacturing, aerospace engineering, and medical device production — cannot tolerate even slight deviations. Precision components ensure:

- Exact Positioning: Critical when measurements or cuts must be perfect.

- Repeatable Results: Essential for manufacturing consistency.

- System Longevity: Quality motion reduces wear and mechanical failure.

- Reduced Errors: Precision reduces costly mistakes and downtime.

Precision motion is at the core of ultra-precision systems and advanced manufacturing technologies.

What Industries Need Precision Motion Components?

Industries We Serve that depend heavily on precision motion solutions include:

- Semiconductor & Electronics: Lithography, wafer inspection, PCB manufacturing.

- Aerospace & Defense: Guidance systems, satellite positioning, turbine engine manufacturing and inspection, and component testing.

- Medical Devices: Surgical robotics, imaging, diagnostics equipment.

- Optics & Metrology: Lens fabrication, laser alignment, measurement devices.

- Industrial Automation: Robotic assembly, quality inspection systems, and many more

What Types of Precision Motion Components Does ABTech Offer?

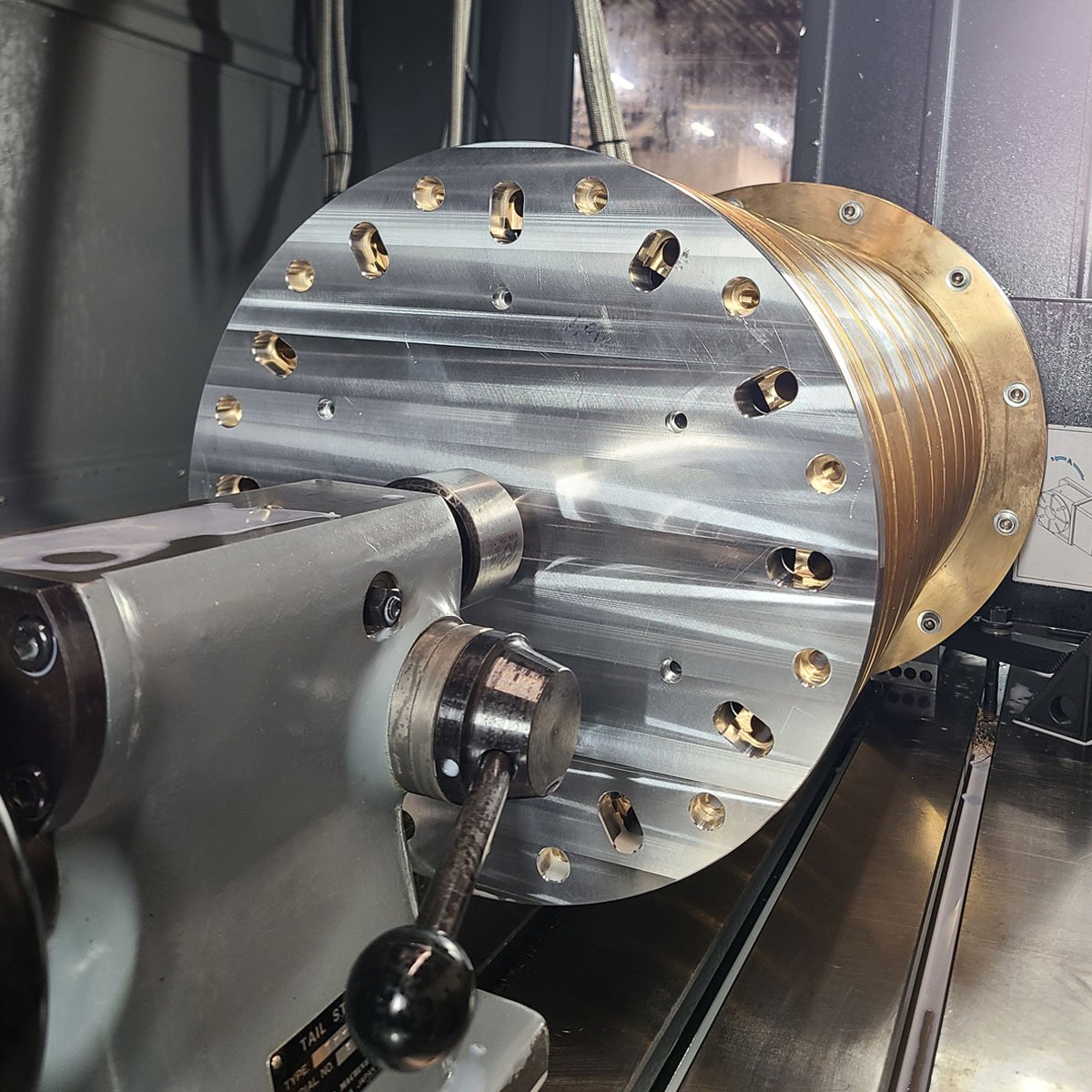

- Rotary Tables — Achieve precise angular positioning with minimal runout. Essential for inspection and machining applications.

- Spindles — Deliver ultra-precise, high-speed rotational motion for tools and measurement equipment.

- Linear Stages — Ensure high-accuracy straight-line movement for positioning tasks.

- Accessories — Include air bearing stages, encoders, magnetic scales, and vibration isolation devices that enhance motion system performance.

Frequently Asked Questions:

What are precision motion components used for?

They are used to achieve extremely accurate and repeatable motion in high-precision manufacturing, inspection, and research environments.

What is the difference between linear stages and rotary tables?

Linear stages provide controlled straight-line movement, while rotary tables enable precise rotational motion.

Can ABTech build custom precision motion solutions?

Yes! We specialize in custom solutions to meet your specific motion control requirements.