Precision manufacturing solutions may require various types of rotary tables. So how do you choose which one is best for your specific needs? In this blog, we’ll walk you through three common types of high-precision rotary tables – air-bearing, oil hydrostatic, and mechanical-bearing – and some key features of each type.

What Is a High Precision Rotary Table?

Rotary tables are positioning devices that are oftentimes used in precision manufacturing applications. More specifically, they are tools that hold parts on rotating axes, which increases productivity, accuracy, and repeatability. As its name implies, high-precision rotary tables help you achieve a greater degree of accuracy.

Air-Bearing Rotary Tables

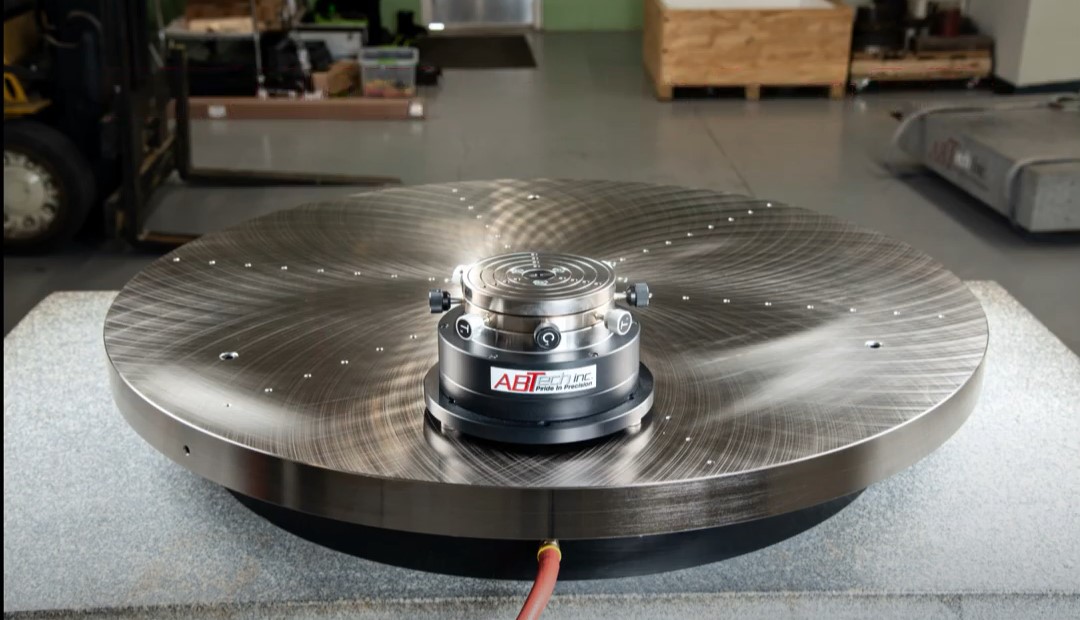

In many cases, air-bearing rotary tables will be the answer. This is due to the fact that they have the capacity to run longer than other kinds. These are exactly what they sound like; with air-bearing rotary tables, parts float on air above the table. With this, there are no contacting parts to wear the machine down, resulting in decades of maintenance-free motion. That is a significant benefit to any piece of air-bearing equipment, but these rotary tables are specifically beneficial for certain applications.

Maximizing metrology productivity can be challenging, but utilizing air bearings can assist in boosting turnover. Additional industries, such as optics, assembly lines, and light machining and grinding, can use them to increase accuracy and productivity as well.

Oil Hydrostatic Rotary Tables

Similar to air bearings, oil hydrostatic rotary tables do not have any contacting mechanical parts, as they float parts on oil. These rotary tables are most commonly used for grinding and machining when smooth and repeatable motion is necessary. They provide high load capacity and can be useful when extreme stiffness is necessary.

Mechanical-Bearing Rotary Tables

Mechanical-bearing rotary tables are a bit different from the other two. Just as the name suggests, this type of rotary table does have moving, touching mechanical parts. And while this sometimes results in a shorter life than the air-bearing or oil hydrostatic tables, many organizations will still consider these over the others. Why? They still offer high performance.

These rotary tables can be used in most applications and provide superior performance in radial, axial, and angular error motions. In all, mechanical-bearing rotary tables do the job; however, it is possible that they will not last as long as other types.

Which Type of High Precision Rotary Table is Best?

Back to the original question of which one is best: all in all, it depends. Generally speaking, air-bearing rotary tables provide the highest accuracy for the longest time. The lack of touching mechanical parts allows this type of rotary table to last decades. However, if you need a stiffer hold, oil hydrostatic could be the better choice. And in other cases, mechanical-bearing rotary tables could be a viable solution for your needs.

To truly decide which high-precision rotary will best meet the needs of your specific application, it’s a good idea to talk it through with an expert. That’s where ABTech can help! Our team takes a solutions-engineering approach to everything we do. Whether it's rotary tables or other precision motion components, don’t hesitate to reach out to one of our experts, who can walk you through the best-fit options for your needs.