When working in manufacturing, measurement systems are oftentimes the key to accuracy. While we learn how to measure with a ruler in grade school, you cannot get those types of measurements with a ruler. Accurate measurement systems in manufacturing environments require extreme precision and exactness.

So which type of system is required for your precision measuring? It depends on the application and industry. You may need to use a roundness gage, a total indicator reading gage, a diameter measurement gage, a thickness gage, or even another type of system, to get exactly what you need.

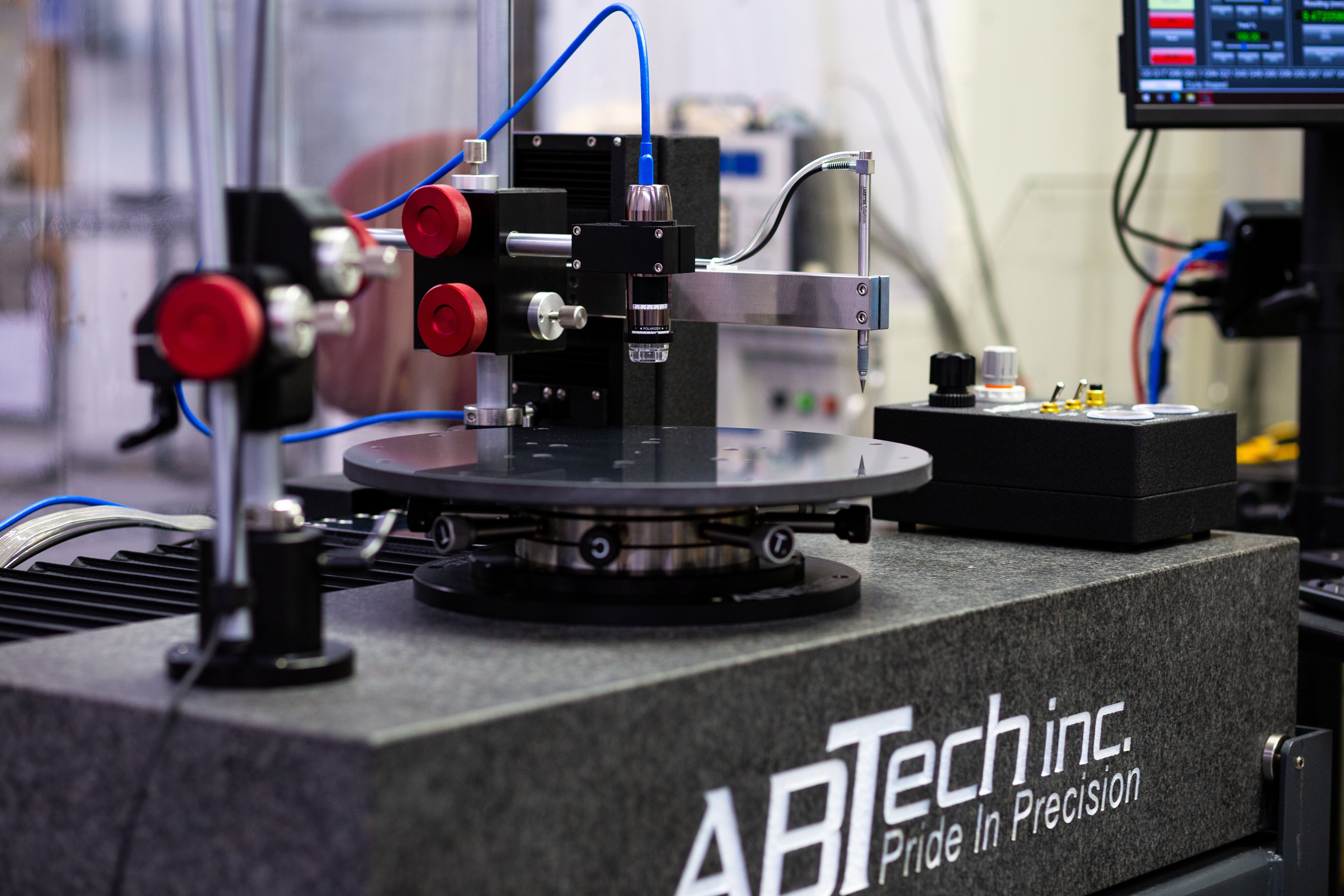

Let’s take a deeper look at what measurement systems actually are, why they are important, and what we have to offer here at ABTech.

What is a manufacturing measurement system?

There are a multitude of different types of measurement systems that are used in manufacturing, each one being quite different. There are roundness gages, which are used to check roundness, runout, flatness, concentricity, parallelism, and perpendicularity. There are also total indicator reading gages for ODs, IDs, and faces of cylindrical parts, which can be used when you are not in need of a full roundness gage. But there are other types of measurement that need to be done in manufacturing, which is where some of these other systems come into play.

Some gages are built for diameter measurements. Diameter gages can be used while a part is still on a machine, such as a lathe or a grinder. There are also thickness gages, used to measure exactly what it sounds like: thickness. All in all, there are measurement systems to fit almost, if not every, precision need in the manufacturing industry. And yes, there is a significant need.

Why are accurate measurement systems essential?

At this point, you may be wondering, so what? What is the purpose of measurement systems that have such exactness? First, in custom manufacturing, accuracy and quality are essential to almost every application. Imagine if the sleeves on your jacket were different lengths, or the wheels on your car were of different diameters. This would lower the quality of the product, and in many cases, render it useless.

When you look more closely at precision manufacturing, the need for accurate measurement systems becomes even more important. For example, thickness gages, which are ideal for measuring precision machine components, are perfect for optic lenses. Accuracy and precision are paramount to the optics industry – just think, what would happen if two lenses were different thicknesses? That could alter vision, or even distribute weight unevenly. While that is just one example, it demonstrates the criticality of accurate measurement systems in manufacturing.

How can my manufacturing firm achieve accurate measurement?

Well, you just so happen to be in the right place. Accurate measurement systems to fit the needs of our customers are our specialty. We have a roundness gage, the standard of which measures parts up to 32 inches in diameter and 2,000 lbs in weight. Our MicroTIR (total indicator reading) gages, measuring the same size parts, are a perfect substitute for the full roundness gage.

Our diameter measurement gage can measure the diameter of parts to 0.001” accuracy. And the aforementioned thickness gages, perfect for lenses, precision ground, or lapped parts, are more accurate than +/- 20 microinches. ABTech also provides a setting master and various measurement accessories to ensure that every exact measurement need is met.

In conclusion, the exactness of measurement can never be compromised in manufacturing environments. Precision measurement is vital to success. Whether measuring roundness or thickness or something else, every measurement matters. If you would like to learn more about how to manufacture your products to a particular accuracy, learn more below or contact our team today.