Spindles serve a critical purpose in many different manufacturing environments, and their purpose varies depending on the application. Here at ABtech, spindles are one of the three main categories of precision motion products that we manufacture. In this blog, we offer a quick guide to the basics: what exactly are spindles? What is the purpose of a spindle? How do you know which type of spindle is best for your application? Read on.

What are precision spindles?

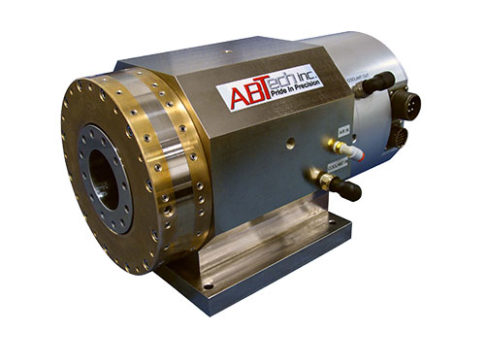

Spindles, in simple terms, are pieces of manufacturing equipment; however, they are more complex than just that. A spindle is a piece of machinery that rotates and offers a fixture to hold a tool or workpiece. The spindle shaft supports, positions, and spins that particular tool.

Some spindles are designed for high-precision applications, allowing for a higher degree of accuracy and reliability. ABTech spindles, for example, have the ability to spin anywhere from 1,000 RPM to 20,000 RPM (and beyond), which is very fast. But why would you need a spindle, especially one of that caliber? Let’s explore.

What are spindles used for?

Precision spindles are actually used for many different applications. They are utilized for diamond turning, grinding, optical scanning, and much more.

Many of these applications are unique and require a custom-designed solution. For example, when a European High-Speed rail company needed a 3D image scanning system to inspect the construction of its rail system, they came to ABTech to design and manufacture a set of high-speed air-bearing spindles. (Read the full story here.)

It is evident that spindles are not a one-size fits all product, and have various uses in many different environments. And this is especially true when considering the different types.

What are the different types of spindles?

There are two major types of spindles: air-bearing spindles and mechanical-bearing spindles. In general, air-bearing spindles, which have no contacting mechanical parts, are best in diamond turning, finish grinding, polishing, PCB drilling, and scanning applications.

On the other hand, mechanical-bearing spindles, which do have contacting mechanical parts, are most useful as stand-alone units or multi-axis assemblies for heavier machining and grinding scenarios.

Which spindle type is best for your application? Keep in mind there are always outliers to these categories and many more uses for spindles beyond what we’ve discussed here. With the numerous uses and the different types, picking the right spindle for your application may pose a challenge. Whether being used for diamond turning or a camera system, there are still several questions to explore.

Want to speak to a spindle manufacturer?

The best way to know which kind is best for your use is to speak with an expert. Reach out to us at ABTech anytime, and we will get you hooked up with the perfect piece of equipment for your needs.