Looking into rotary tables but unsure where to start? You’re not alone. From cleanroom compatibility to tariff impacts, the questions you ask today shape your success tomorrow—especially in high-precision industries like optics, aerospace, and semiconductor manufacturing.

Here are some frequently asked questions built specifically for purchasing teams, engineering leads, and operations managers evaluating rotary tables.

What is a rotary table used for?

A rotary table is used to provide precise rotational motion for positioning, inspection, machining, or alignment. It supports applications in optics manufacturing, turbine inspection, semiconductor metrology, and more.

Which industries use rotary tables the most?

Industries that rely heavily on rotary tables include optics, aerospace, semiconductor, energy production, and advanced manufacturing. Applications range from laser alignment and wafer inspection to satellite component assembly.

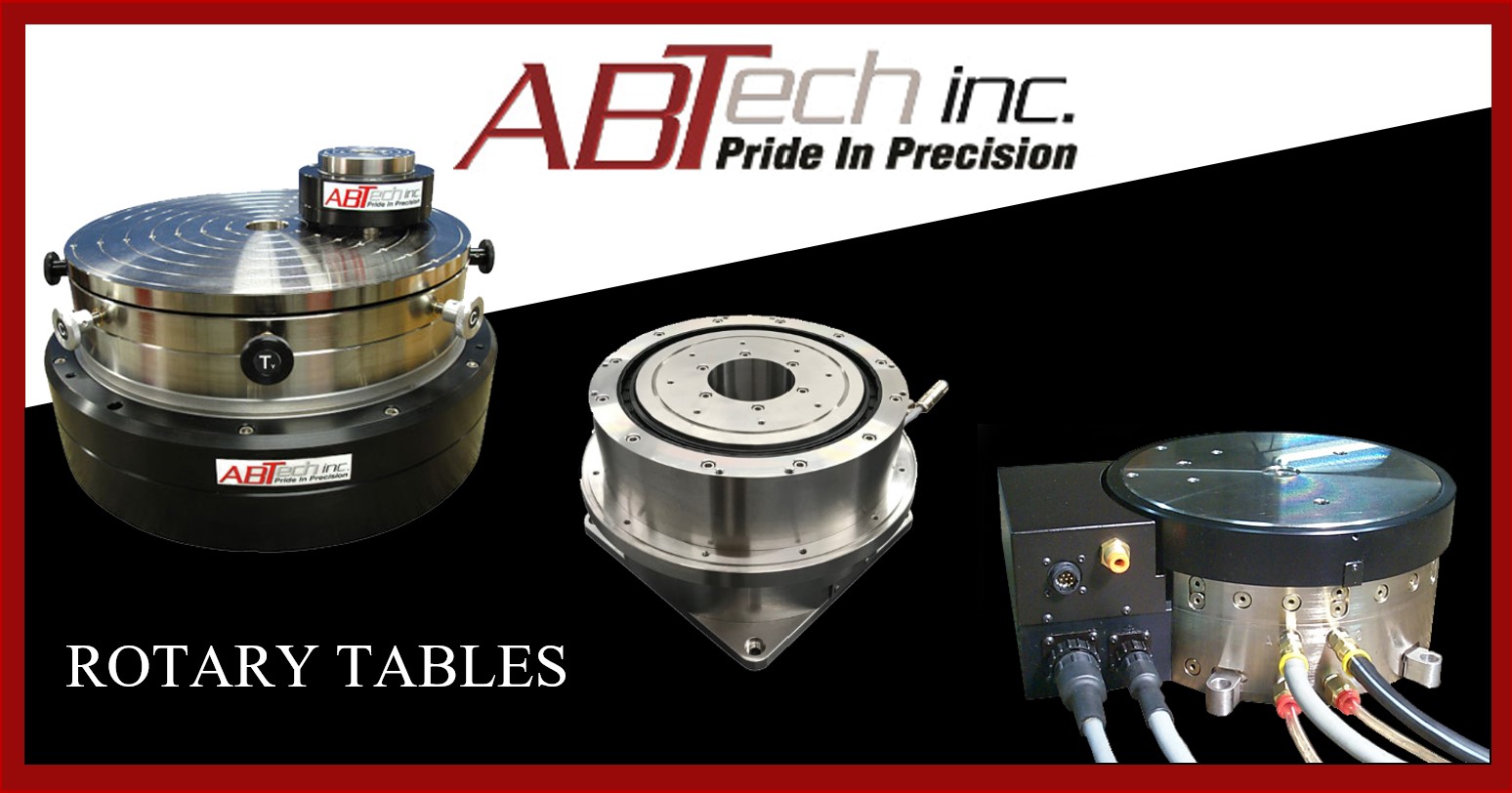

What types of rotary tables does ABTech offer?

ABTech offers three primary types:

- Air-Bearing Rotary Tables for nanometer-level accuracy and cleanroom environments

- Oil Hydrostatic Rotary Tables for heavy load, high-stiffness aerospace and energy applications

- Mechanical-Bearing Rotary Tables for cost-effective, high-performance motion in industrial systems

What’s the difference between air-bearing and mechanical-bearing rotary tables?

Air-bearing rotary tables offer frictionless, contact-free rotation ideal for high-precision, cleanroom-compatible operations. Mechanical-bearing tables are more rugged and cost-effective, with micron-level repeatability for general-purpose applications.

Can rotary tables be used in cleanroom environments?

Yes. ABTech designs cleanroom-ready rotary tables, especially air-bearing rotary tables, which are ideal for ISO 14644 cleanroom compliance in optics and semiconductor environments.

How do I know if I need a custom rotary table?

You likely need a custom rotary table if you require:

- Sub-micron or nanometer accuracy

- Integration with vacuum, encoder, or feedback systems

- High-load handling (e.g., turbines or satellite parts)

- Compliance with standards like AS9100, NQA-1, or ISO 10110

Are rotary tables affected by tariffs?

Yes—but ABTech products are largely protected. With recent tariff increases on imported steel and aluminum under the Trump administration, many foreign-made components face rising costs and delays.

ABTech rotary tables are U.S.-made, helping you avoid these added expenses while securing faster lead times and more stable pricing. It’s not just precision you’re investing in—it’s cost control and sourcing confidence.

Can rotary tables be integrated with automation systems?

Absolutely. ABTech rotary tables are compatible with motion control systems, CNC platforms, robotic automation, and smart manufacturing solutions. They support digital feedback, traceability, and real-time data integration.

What questions should I ask when sourcing a rotary table?

- What level of accuracy do I need (micron vs nanometer)?

- What is my required load capacity?

- Will the table be used in a cleanroom?

- Do I need standard or custom engineering?

- How will tariffs affect my sourcing strategy?

Where can I get support for specifying a rotary table?

You can contact ABTech’s application engineering team for guidance. We offer consultations, quotes, and customized specs based on your industry, application, and compliance needs.