When was the last time you evaluated the true performance and cost impact of your spindle—not just its specs, but what it’s doing (or not doing) for your bottom line?

In high-stakes industries like aerospace machining, optics manufacturing, and precision manufacturing, a single flawed part can scrap thousands in material, delay deliveries, and damage customer trust. The right precision spindle doesn’t just meet tolerances—it protects your margins, enhances throughput, and opens doors to new capabilities.

This blog explores how investing in an ABTech precision spindle delivers measurable ROI by solving problems that undercut performance, profitability, and competitiveness—especially when every micron matters.

Problem: Managing Long-Term Operational Costs and Equipment Lifecycles

Solution: An Engineered Spindle with Lower Total Cost of Ownership (TCO)

The initial purchase price of a component is only one part of the equation. A true cost analysis must include the Total Cost of Ownership (TCO), which factors in longevity, maintenance, and reliability.

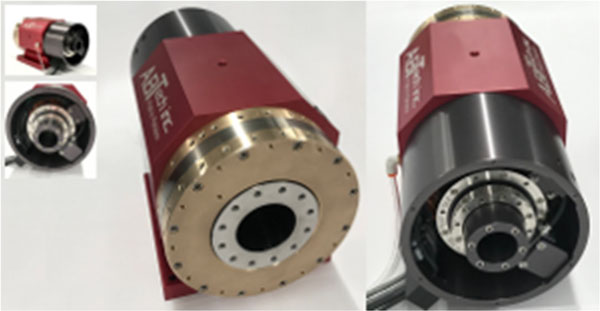

- Robust Design: Every precision spindle features a hardened 440C stainless steel shaft, a 660 bearing bronze journal, and optimized structural damping for long-term durability.

- Frictionless Reliability: Our air bearing spindles offer decades of service without wear. Mechanical spindles use high-quality angular contact bearings engineered to tight tolerances, extending service life and reducing downtime.

Problem: Hidden Costs from "Good Enough" Spindle Performance

Solution: Mitigating Inaccuracy to Protect Your Bottom Line

A spindle that is merely "good enough" often introduces hidden costs that erode profitability.

- Reduce Scrap in Manufacturing: In critical environments like optics and precision manufacturing, subpar rotation leads to costly rejections. Our precision spindle bearings maintain consistent accuracy.

- Prevent Tool Chatter: Balanced, vibration-free rotation protects your tools. Advanced spindle technology helps extend tool life and improve surface finishes.

- Combat Thermal Drift: With active airflow, our air bearing spindle maintains thermal stability—even during long, high-speed runs. This is crucial for maintaining spec tolerance throughout shifts.

Problem: Competing in a Market with Increasing Demand

Solution: Custom High Speed Spindles that Drive Growth

Our spindles aren’t just accurate—they’re adaptable to evolving needs and production goals.

- Expand Production Capacity: Run at speeds exceeding 30,000 RPM with consistency. Our custom high speed spindles are built for throughput without compromise.

- Strengthen Supplier Relationships: Deliver ultra-consistent quality and reinforce your value to customers. Use our air turbine spindles and superior spindles to gain the competitive edge.

Why Choose Us for Your Precision Motion Systems

Our design philosophy is centered on providing application-specific custom solutions. All spindles can be customized with a variety of options to create a turnkey precision motion system for your unique OEM needs.

- Motor Drives and Controls: We integrate high-performance brushless DC servo motors and high-resolution encoders seamlessly with advanced motion controllers.

- Versatile Mounting Options: Choose from flange, foot, athermal, and other mounting configurations to suit your specific machine architecture.

- Customizable Accessories: Further options include vacuum worktables, digital readout (DRO) displays, inspection-grade granite surface plates, liquid cooling provisions, and much more.

Our Product Portfolio

Explore our full lineup of precision motion systems and components:

- Air-Bearing Spindles

- Mechanical Bearing Spindles

- Rotary Table

- Linear Stages

- Accessories and other integrated precision components

Can’t Find What You’re Looking For?

Our experts will co-engineer a custom solution to your exact specifications.

A Partnership in Precision

Choosing a precision spindle is more than a transaction; it's the beginning of a partnership. Our team of precision motion experts works closely with you from the initial design consultation through to final integration and support. We don't just sell components; we provide fully engineered solutions backed by decades of experience solving the most complex motion challenges. This collaborative process ensures you receive a system that is perfectly optimized for your application, delivering reliable performance for years to come.

Quick links to Our Spindles

ABTech is proud to be Made in the U.S.A of U.S. and imported parts.