ABTech's primary focus is on collaborating with OEMs. To us, OEMS are companies that build complete machines, platforms, and systems that rely on proven motion components at the heart of their design.

ABTech partners with OEMs to supply precision spindles, air-bearing rotary tables, and linear stages that are integrated into larger machines, either as upgrades to existing components or as enabling technology for entirely new systems. Simply put, we design and manufacture the critical motion components that enable machines, platforms, and systems to perform better, last longer, and operate more reliably.

In OEM environments where performance margins are tight and extreme accuracy is essential, air bearing technology continues to set the benchmark for precision, reliability, and scalability. Backed by precision manufacturing and decades of expertise in air-bearing spindle technology, ABTech helps manufacturers design systems that consistently perform at the highest level, reliably. At ABTech, air bearings aren’t just components—they’re the foundation that allows our partners (OEMs) to build bigger, better, and more robust systems with confidence. From high-precision spindles to large-scale air-bearing rotary tables, our technology enables OEMs to push performance boundaries without compromising reliability.

As part of our 2026 focus, we’ve invested in heavier-duty equipment, expanded capacity, and advanced manufacturing to meet growing demand for large, high-performance systems. Our production and partnership model are purpose-built for machine manufacturers pushing the limits of size, load, and accuracy.

Why Air Bearings Matter in OEM System Performance

Air bearings eliminate concerns of friction, wear, and lubrication by replacing mechanical contact with a thin, stable film of air. For OEMs designing next-generation equipment, this delivers several critical advantages:

- Zero mechanical wear, ensuring long-term accuracy and repeatability

- Exceptional stiffness and load capacity, even at large scales

- Ultra-smooth motion, critical for inspection, metrology, and advanced manufacturing

- Thermal stability, supporting consistent performance in demanding environments

When integrated correctly, air bearings not only improve motion but also elevate the reliability of the entire system.

Building Bigger Stronger Systems — On Purpose

Our partners’ systems are larger, heavier, and more complex than ever. ABTech has scaled in step with them.

We are currently producing a series of large AT and HDRT Rotary Tables for a key client—tables designed to support significant loads while maintaining the precision expected from air bearing technology. These projects reflect a broader shift in our capabilities: larger rotary platforms, higher torque requirements, and tighter performance envelopes.

That momentum continues with the onboarding of a new international OEM partner, who approached ABTech specifically for our expertise in large rotary tables. Their systems demand not only size and capacity, but absolute confidence in long-term performance—exactly where air bearings excel.

Advancing What's Possible Through Material Innovation

One of our longest-standing OEM relationships is entering a new chapter, one that underscores how air bearings evolve along with our customers’ ambitions.

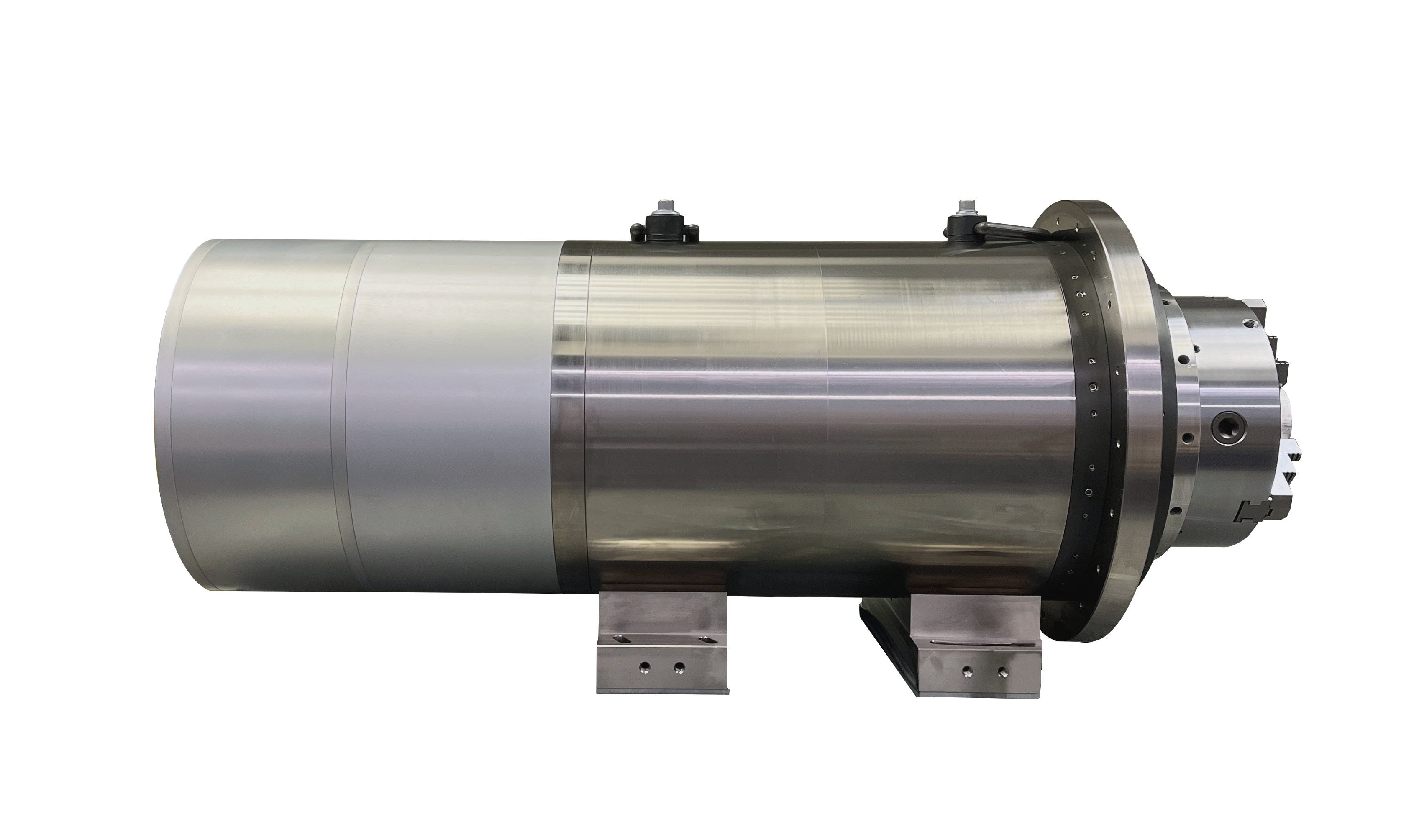

This client has expanded their commitment with ABTech, increasing orders for what are now among the largest high-precision air-bearing spindles currently being built in the world. Beyond that, ABTech is continuously improving it’s designs and production processes, applying the latest manufacturing breakthroughs to enhance this spindle program. By implementing a lighter-weight, higher-performance material, we’ve been able to:

- Improve overall spindle efficiency

- Enhance dynamic performance without sacrificing capacities

- Extend system longevity while reducing operational load

This is a clear example of how air bearing systems aren’t static. They can be refined, reinforced, and reimagined as technology and requirements advance.

Proven OEM Partnerships Across Industries

ABTech’s air bearing solutions are trusted by OEMs (manufacturers of metrology systems and manufacturing tools) across a wide range of industries, including:

- Optics and photonics

- Semiconductor manufacturing

- Aerospace and energy systems

- Automotive and advanced inspection platforms

In many cases, our work extends well beyond a single component, encompassing high-precision spindles, air-bearing rotary tables, and fully integrated motion systems designed around OEM-specific requirements. We collaborate on fully integrated systems, combining rotary tables, spindles, and precision motion assemblies into application-specific platforms that become core to our customers’ products.

How ABTech Earns OEM Trust

OEM partnerships are built over years, not transactions. Our process is designed to reduce risk, increase transparency, and ensure long-term success:

- Discovery – We invest time upfront to understand the application, constraints, and performance goals.

- Collaboration – Engineers work directly with the OEM’s engineering and production teams to co-develop the right solution.

- Quotation – Clear, realistic proposals grounded in manufacturability and performance.

- Execution – Precision manufacturing backed by rigorous quality control.

- Implementation – Support during integration to ensure the system performs as intended.

- Follow-Up – Ongoing engagement to support upgrades, scaling, and future programs.

This proven approach is why OEM partners return to ABTech when their systems grow larger, more complex, and more demanding.

A Partner for What's Next

As OEM systems continue to scale, air bearings will remain a critical enabler of performance and reliability. By investing in heavier-duty infrastructure, advanced materials, and collaborative engineering, ABTech is positioned to support what comes next; whether that’s the next generation of large-format rotary tables, world-class air-bearing spindles, or fully integrated precision systems.

If you’re building something bigger, stronger, and more ambitious, we’re ready to build it with you.

Contact us today to start the conversation.

Can’t Find What You’re Looking For?

Our experts can help you design a fully custom solution.

Quick links to our precision motion components: