In high-stakes industries like energy production and optics manufacturing, precision isn’t optional—it’s the difference between meeting spec and falling short, winning contracts or missing deadlines. And when motion matters, rotary tables are at the core of performance.

But here’s the big question: should you choose a standard rotary table or invest in a custom-engineered solution?

This guide helps engineering managers, procurement teams, and system integrators evaluate when off-the-shelf is enough—and when customization becomes essential to hit performance, compliance, and ROI targets.

Understanding the Difference: Custom vs. Standard Rotary Tables

Standard Rotary Tables:

- Pre-configured units with fixed dimensions, load capacity, and motion specs

- Faster delivery, lower initial investment

- Suitable for general-purpose automation or inspection tasks

Custom Rotary Tables:

- Built to meet exact load, environment, accuracy, and integration needs

- Engineered to support high-performance and compliance-critical workflows

- Designed for long-term ROI and technical scalability

Where Custom Makes the Difference: Energy Industry Applications

The energy sector—especially nuclear and turbine manufacturing—presents high-force, high-stakes applications where precision and safety are non-negotiable.

Key Customization Benefits:

- Load handling: Custom oil hydrostatic or mechanical-bearing tables support heavy components like turbine rotors or containment rings

- Thermal control: Materials and lubrication optimized for heat-intensive environments

- Certifications: Designed to meet NQA-1, ISO 9001, and vendor-specific nuclear quality programs

Precision in Optics: Why Off-the-Shelf Often Isn’t Enough

Optics manufacturing demands ultra-clean, ultra-stable, and ultra-precise rotation—especially in lens polishing, laser alignment, and metrology.

Why Custom Wins:

- Cleanroom compliance: Custom air-bearing designs with materials and coatings that meet ISO 14644 and ISO 10110

- Non-contact motion: Frictionless rotation to prevent particle generation

- Tooling integration: Custom fixturing, vacuum chucks, and motion controllers for high-resolution systems

Cost vs. Value: Making the Right Investment

While standard tables offer a quicker path to implementation, custom rotary tables offer:

- Superior long-term ROI

- Reduced integration risk

- Optimized part quality and throughput

- Enhanced compliance and traceability

For high-value manufacturing operations, custom pays for itself in reduced downtime, higher accuracy, and fewer failed inspections.

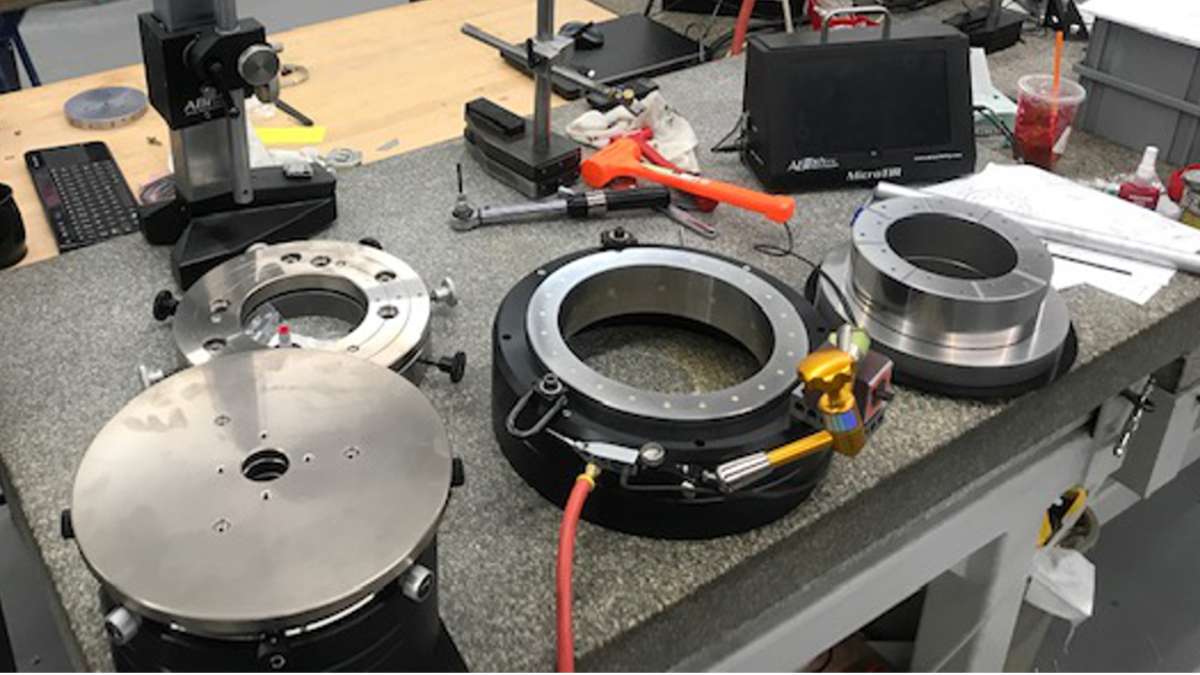

How ABTech Supports Custom Motion Solutions

At ABTech, we specialize in designing precision motion systems tailored to industry-specific requirements in energy, optics, and other ultra-precision applications.

Our Custom Solutions Include:

- Rotary tables with air, oil hydrostatic, or mechanical bearings

- Integration with encoders, vacuum systems, CNC automation, and data feedback tools

- Built-in compliance with nuclear, aerospace, and cleanroom certifications

Final Thought: When the Margin for Error is Zero, Custom Makes Sense

If you’re dealing with challenging specs, demanding clients, or zero-failure-tolerance workflows, the right rotary table isn’t just a component—it’s a strategic investment.

Let’s build a solution that’s engineered for your precision environment.