Multi-functional Air Bearing Machines for NASA NuStar X-ray Telescope

NASA needed a machine that would safely and quickly produce optics for their long-delayed NuSTAR X-ray telescope. So the scientists as NASA challenged ABTech to develop a multifunctional machine that would act as a grinding lathe, an indexing tool for raster grinding, and an assembly station – all in one. ABTech met the challenge. The machines were delivered to Columbia University’s Nevis Astrophysics Lab in quick fashion, helping to put the project back on schedule.

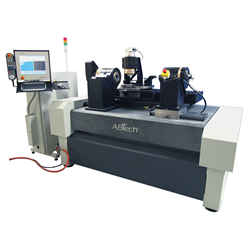

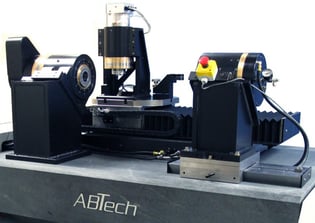

The two turnkey systems that were developed are air bearing-based optics assembly machines. The systems are capable of grinding the graphite mounting surfaces for 4,680 optical glass segments so that the cylindrical optics modules for NASA’s NuSTAR telescope could be assembled. Each multi-function machine incorporates an ultra-precision ABTech designed and manufactured air bearing with direct drive motors and high-resolution encoders. The machines also include an extended travel Y-axis stacked onto dual parallel linear air bearings, set with a wide stance to serve as the X-axis.

An ABTech high-speed air bearing spindle was mounted on a unique custom-designed indexing turret. Coaxial head stock and tailstock air bearing spindles make up the precision lathe. This required ABTech to customize the CNC controller to operate in dual-functioning lathe and indexing modes.

NASA found what many of our customers have found – that ABTech is fully committed to working in partnership to solve its customer’s most unique needs. Based on the technical merits of our proposal and our proven track record of delivering custom systems within critical time frames, we were awarded the contract.

System Feature Summary

- LAB-R series linear stacked air bearing stages straight and flat to less than 20 micro-inches (0.5 micron) over the full 24 inch (600 mm) travel

- Air bearing work holding and tailstock spindles (model WHS-180) for lathe operation or holding position of the optic during assembly and grinding

- SP-125 high-speed air bearing spindle for grinding graphite mounting surfaces

- Indexing turret assembly to quickly and easily transition between diamond turning, grinding and LVDT measurements

- Granite surface plate and air bag style vibration isolation base frame

- Ergonomic and multi-functional platform with both front and rear access

- Customized Delta Tau CNC controller and electrical control cabinet

See results of the telescope on the NuSTAR CalTech website: www.nustar.caltech.edu