High precision does not become less demanding as systems get larger; if anything, the challenges increase. Maintaining stiffness, load capacity, and extremely low error motion at scale requires more than refined designs; it requires sustained investment, engineering discipline, and manufacturing capability built for the long term.

ABTech’s high-precision air-bearing spindles are designed from the ground up to support demanding OEM applications where accuracy and repeatability are critical. Built on proven, robust architectures, these spindles deliver high stiffness, exceptional load capacity, and ultra-low error motion across applications, including precision machining, grinding, single-point diamond turning, and inspection and metrology.

To support a wide range of operating requirements, ABTech spindles are available in multiple sizes and speed configurations. Integral brushless DC motors and encoders can be optimized for low-speed work holding or higher-speed grinding and scanning applications. Flexible mounting options(including flange, foot, and a-thermal configurations) allow for straightforward system integration, while optional motion controllers provide digital amplification, programmable control, real-time speed feedback, and seamless CNC compatibility.

Smart Investment Backed by Production Programs

What differentiates ABTech is not only performance, but the ability to extend that performance to increasingly large systems. Driven by ongoing OEM production programs, ABTech has made significant investments in large-scale equipment, expanded its infrastructure, and enhanced its engineering resources. These investments enable the manufacture of ultra-precision motion systems at sizes few suppliers can support.

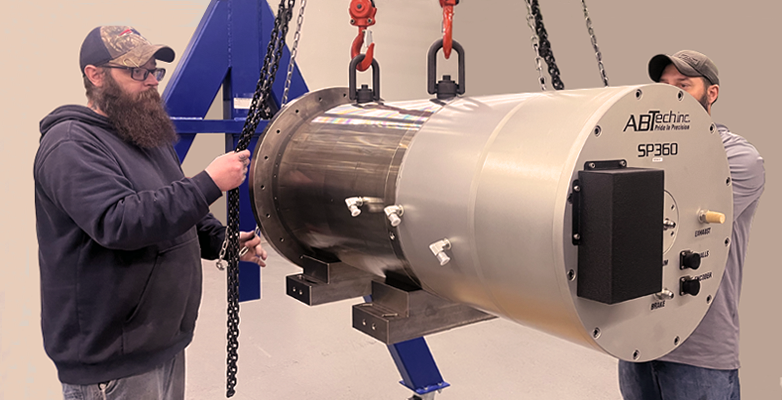

The SP 360: A Milestone in Scale

The SP 360, ABTech’s largest spindle to date, represents the latest step in this evolution. Developed as part of a long-term OEM production program, it serves as a clear indicator of ABTech’s trajectory: scaling ultra-precision capability to meet the next generation of application demands.

SP 360 Overview:

Radial and Axial Working loads of > 900 lbs (4 kN)

Radial and Axial Error Motions at maximum speed <20u" (.50 microns)

Torque: >175 ft*lbs (225 N*m)

Angular Position Accuracy: < 2 arcsec

From Our Leadership

"While repeatable and low error motions are typically the core reason to integrate air bearings into machine tools, that is only the beginning for our engineers. Each application brings opportunities to create a product that greatly enhances system performance. Whether it be controlling the ultimate position accuracy, seeking out the last microinch of error motions, or providing functionality such as unique workholding systems, ABTech's team provides the customer with a comprehensive solution. This SP360 is a perfect case study of this effort. Not only is this a massive spindle, but it is jam-packed with capabilities and exceeds an extensive array of specifications."

— Chris Abbott, Chief Operating Officer, ABTech

Built Around the Application

With a modular design philosophy and complete in-house engineering support, ABTech responds quickly to deliver spindle solutions tailored to each customer’s unique requirements, without the limitations of a standard line of catalog offerings.

As precision requirements grow and system scale increases, ABTech continues to build the capabilities needed to support what comes next.

Contact us today to start the conversation.

Can’t Find What You’re Looking For?

Our experts can help you design a fully custom solution.

Quick links to our precision motion components: